Introduction

No matter what a customer is looking to have printed, the whole process starts with design. And to bring to an even more granular level, that design lives in a design file, ready to be brought to life, built upon, and transformed into different iterations and outputs.

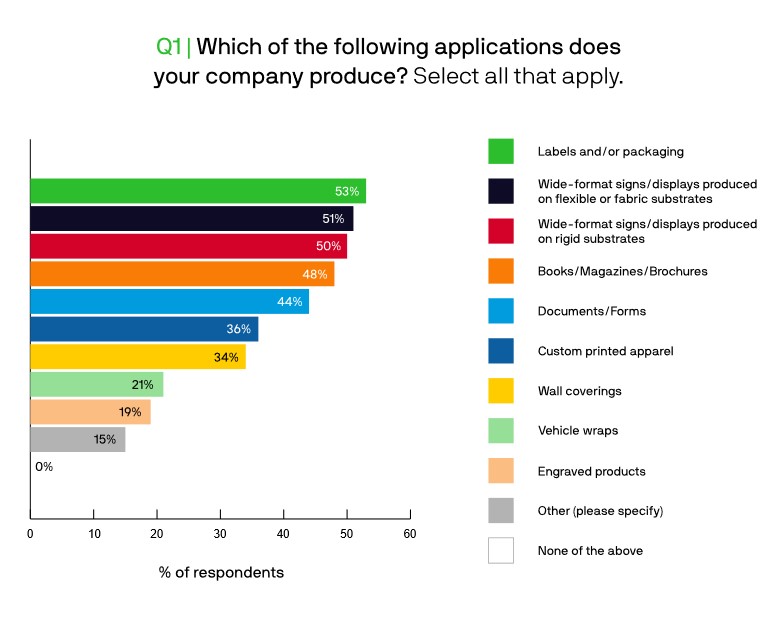

For instance, a business may be looking for a sign to promote an event, packaging for a new product, or a vehicle wrap to take their brand on the road. Regardless of what needs to be printed, the project starts with a graphic design file.

In this report we will examine the integral role graphic design software delivers to the print industry and how small investments in keeping design software current, can help increase efficiencies in the pressroom, reduce waste, enhance color management, and more! All while resulting in cost savings and improved customer service for print service providers.

That said, perhaps one of the most impactful steps that commercial printers can take towards maximizing efficiency and reducing waste is upgrading their graphic design software immediately.

Respondents who did so were 45% more likely to report that they are highly efficient in the prepress stages, as opposed to respondents who delayed upgrading or chose to stick with outdated software.

The clear takeaway?

"The consequences of not updating graphic design software include stagnation of employee knowledge, negative productivity impacts due to employee time spent hunting down missing elements and errant fonts, and lack of employee understanding of how these improvements dovetail with management's call for greater efficiency."

- Marina Poropat Joyce,

Author of Designing for Print, The Art & Science

No matter what a customer is looking to have printed, the whole process starts with design. And to bring to an even more granular level, that design lives in a design file, ready to be brought to life, built upon, and transformed into different iterations and outputs.

For instance, a business may be looking for a sign to promote an event, packaging for a new product, or a vehicle wrap to take their brand on the road. Regardless of what needs to be printed, the project starts with a graphic design file.

In this report we will examine the integral role graphic design software delivers to the print industry and how small investments in keeping design software current, can help increase efficiencies in the pressroom, reduce waste, enhance color management, and more! All while resulting in cost savings and improved customer service for print service providers.

That said, perhaps one of the most impactful steps that commercial printers can take toward maximizing efficiency and reducing waste is upgrading their graphic design software immediately.

Respondents who did so were 45% more likely to report that they were highly efficient in the prepress stages, as opposed to respondents who delayed upgrading or chose to stick with outdated software.

Read on to learn more about the methodology behind the survey, our findings, and how commercial printers can maximize efficiency and reduce waste going forward.

Research methodology

NAPCO Research conducted an online survey of print service providers in February 2023. The survey was sent to printers spanning commercial print, wide-format graphics, and apparel decoration. In total, exactly 200 printers completed the survey.

How do printing companies rate their design to output performance?

Perhaps the most important aspect for commercial printing to consider is how effectively organizations take those essential design files (mentioned above) and how various tools and solutions perform, to transform them into the desired outputs.

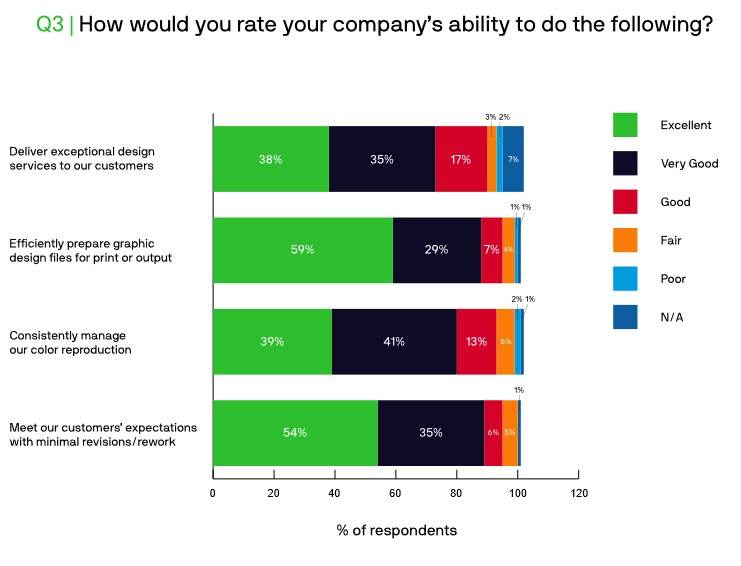

We asked printers how they rated their designs to output performance and the results told a clear story; while more than half of respondents state their companies offer excellent performance in efficiently preparing graphic design files for print or output (59%) and meeting customer expectations with minimal revisions/rework (54%), there is clear room for improvement.

Top areas for improvement in output performance as indicated by the survey results:

- Color management

- Providing stand out design services to customers

- Implementing successful waste reduction strategies

In fact, when asked about color management, just 31% strongly agree that their company implements and follows through on effective color management strategies. Even fewer (25%) state they strongly agree that their companies implement and follow through on effective waste reduction strategies.

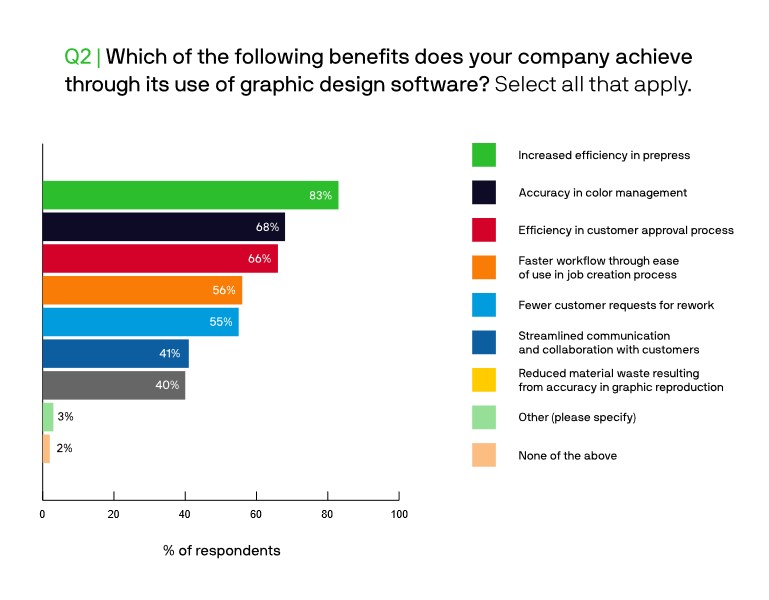

While respondents did indicate that they are seeing advantages from their use of graphic design software, particularly as it pertains to efficiency in the prepress stage, the data gathered in this survey makes clear that there are areas of concern that printers should be focusing on. With better use of graphic design software, companies can make cost-effective improvements that will be reflected in their bottom lines.

Understanding underlying inefficiencies

Beyond graphic software’s ability to maximize a brand direction or creative vision, are features and tools that can Ensure efficiency in print production is essential, particularly as demand for fast turnaround times from customers is on the rise. With the advent of digital printing technologies, and a growing need for design flexibility, brand owners and marketers have become increasingly accustomed to on-demand print ordering and production. Accordingly, they are in need of print partners that can deliver high-quality results on limited notice.

Print service providers indicate that they currently perform well in prepress efficiency, with 88% of respondents stating that their companies are either very good (29%) or excellent (59%) in efficiently preparing graphic design files for print or output. This strength among printers can be tied directly to their use of graphic design software, as 83% of respondents stated that increased efficiency in prepress is a distinct advantage provided to them via their software solutions.

Prepress efficiency is a nuanced term however, and digging deeper uncovers some processes where inefficiency pitfalls persist. Color reproduction, an area in which brands are becoming increasingly stringent in their demands, emerged as a focal point print service providers should be honing in on.

When asked to rate their company’s performance in consistently managing its color reproduction, just 39% of respondents indicated their performance was excellent. While another 41% rated their performance as very good, this is an area of the print production process where excellence should be the norm. Similarly, when asked if their company implements and follows through on effective color management strategies, just 31% — less than one-third of respondents — stated they strongly agreed.

Print accuracy impacts

This lack of confidence in color management can be tied into respondents’ indication that customer revisions and rework are impacting their productivity. For example, 54% of respondents stated their companies provide excellent performance in meeting customer expectations with minimal revisions or rework.

Similarly, nailing a print job on the first production run is key to success for both printers and their customers. On the print side, meeting expectations on the first try ensures that the presses are not tied up with a single job for an extended period. For customers, it means that their print campaigns will not be delayed.

When asked specifically if they consistently meet customer expectations on the first attempt, a little over half or 61% of respondents stated they strongly agree.

Strategizing for waste reduction and efficiency improvements

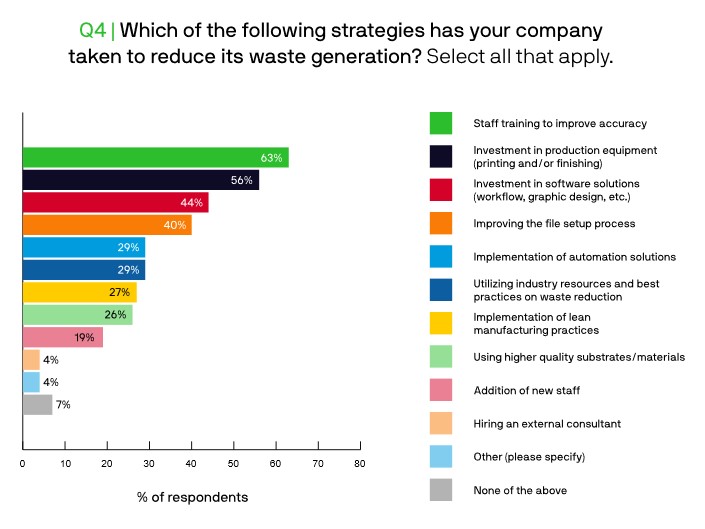

By improving accuracy in print production, print service providers will, in turn, reduce the amount of waste produced by their facilities. When surveying the industry about their companies’ waste reduction strategies, we discovered that there is clear room for improvement.

Just one-quarter of respondents strongly agreed that their company implements and follows through on waste reduction strategies. This is a concerning statistic in regard to both print service providers’ need to maximize their production efficiency and associated costs as well as the desire to reduce their environmental impact or carbon footprint. That said, when asked about the strategies they have taken to improve their waste reduction, respondents indicated that a variety of approaches have been attempted.

The top response from respondents asked to outline their strategies in waste reduction clarifies that printers are looking internally first. In fact, 63% of respondents stated that they have pushed staff training to improve accuracy, but as indicated in the responses to our questions about overall accuracy, it is evident that further technological solutions are necessary to improve the waste situation in the commercial printing realm.

industry to accomplish that is to invest in working with the tool providers, even if there are associated training costs.

"We know that staff training often takes a back seat compared to labor shortages and the pressure of meeting deadlines. When staff aren't trained on everything that their suite of graphic design software offers, it leads to more waste due to design mistakes and a tendency to blame the tools."

-Industry Analyst Pat McGrew (McGrewGroup)

The second most common strategy for waste reduction is increasing investment in production equipment, specifically printing and finishing hardware. Meanwhile, less than half of respondents (44%) stated they made an investment in software solutions aimed at reducing waste.

However, the data indicates that software, which typically carries a much smaller price tag than capital equipment, is an ideal tool for waste reduction. In fact, when presented with several waste reduction attributes, most respondents indicated that their graphic design software has helped them achieve these advantages.

The impact of graphic design software on waste reduction and efficiency:

of respondents stated that their use of graphic design software has been beneficial in increasing efficiency in print job creation.

saw increased efficiency in the design approval process.

stated that graphic design software helped them avoid reruns due to improved graphic reproduction accuracy.

found that graphic design software improved their color management capabilities.

Breaking down these various advantages indicates how effective graphic design software can be in reducing both time and material waste. Efficiency in job creation, for example, gets jobs on press faster, minimizing downtime and keeping workflows in motion.

Meanwhile, reducing the number of job reruns is key to both time and material waste reduction. Spending time resetting a job after it has already been run, the press changed over, and finishing processes complete can be frustrating.

Additionally, tying up a press for an extended period of time to produce a rush job while other tickets are waiting can make for a backlog that is difficult to dig out of. On the material side, printing a job and having it get declined by a customer is costly and wasteful, especially at a time when sourcing substrates can be challenging.

Improving efficiency in the design approval process is also a benefit to printers and their customers, as it helps get jobs on press faster, results in streamlined communications throughout the revision process, and ensures that all parties are on the same page regarding the final design.

At the same time, enhanced color management can be tied back to minimizing reruns, as brand owners and marketers have become increasingly discerning regarding color. Printers that accurately hit their colors on the first try will ensure consistency throughout the run, resulting in minimal rework.

Making a business investment to increase efficiency

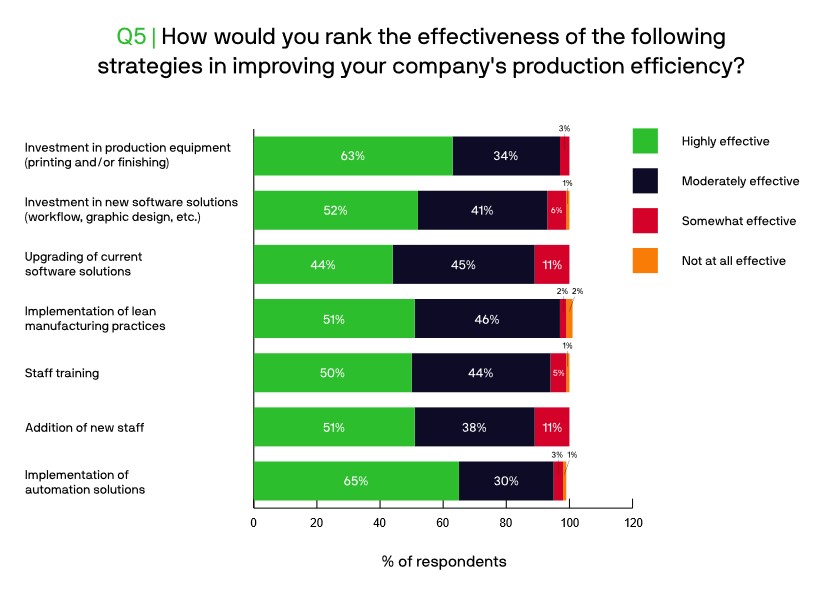

On the production efficiency side, much of the focus is again on investment in production equipment, as 76% of respondents stated they have made a capital investment in printing and/or finishing hardware to boost their efficiency.

While print service providers should have an eye on the latest production equipment and its advancements in speed and automation, there are less costly solutions available that can help to improve efficiency. In fact, the latest software solutions, including graphic design software, can be used as a springboard to faster production.

Accordingly, it is encouraging to see that 59% of respondents stated that they have made an upgrade to a current software solution to increase efficiency since software is a component of the production process that is relatively simple to consistently maintain and upgrade to ensure maximum productivity.

While an upgrade in software may not lead to the same influx of efficiency that can be realized from retiring an old press in favor of a new model, printers that reported making a software upgrade to improve efficiency largely claimed success. Of those respondents, 93% stated that making a software upgrade was at least moderately effective, with 52% stating that it was highly effective.

Hesitance to upgrade leads to missed opportunities

Despite the evidence that staying on top of software upgrades leads to increased efficiency and waste reduction, a concerning quantity of print service providers are hesitant to upgrade their existing solutions. For many design software offerings, upgrades to the latest version are included as part of the subscription price, so opting not to upgrade can result in leaving production efficiency advantages on the table.

While access to the latest software solutions at a minimal cost should be enticing to print service providers, almost half of respondents (46%) state that they assess the changes to the software before moving forward with an upgrade. This hesitancy to upgrade was the top response when survey takers were asked to best describe their company’s approach to upgrading their primary graphic design software when a new version is released. Instant upgrades did appeal to the other half of the respondent base, with 38% stating their upgrades happen automatically and 13% stating that their company elects to upgrade immediately.

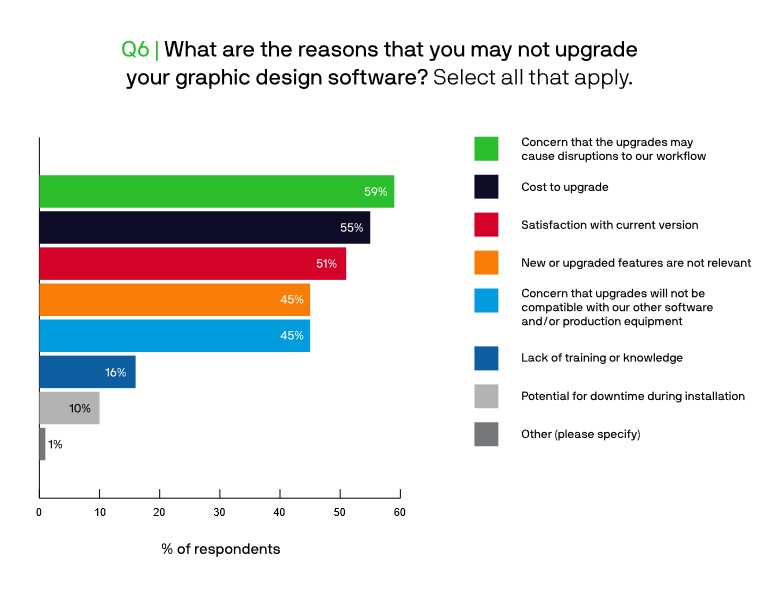

Respondents that stated they either assessed the changes before moving forward with an upgrade and those that stated they elected to not upgrade their graphic design software were presented with a follow-up question asking them to select the various reasons they may choose not to upgrade their software. The responses indicated that there are widespread misconceptions regarding software upgrades, including a notion that upgrading would upset the business’s current workflow.

This concern that upgrades would cause workflow disruptions was the top response at 59% of respondents. This was followed by the cost of an upgrade (55%), and satisfaction with the current version (51%). Just less than half of respondents (45% each) expressed concern that new or upgraded features would not be relevant and that upgrades would not be compatible with other existing software or equipment.

The concern over software upgrades causing workflow disruptions may make sense at surface level, particularly if the existing software version is functioning well enough for the company to get by. Introducing any new workflow solution can result in time needed for users to get up to speed on training and learning the new features that would come up during an upgrade.

However, design software platforms used in the print industry are largely universal in their integration capabilities. What’s more, upgraded features often provide significant efficiency gains that once implemented would negate any slowdowns during installation and training.

Regarding cost, graphic design software that is offered in a subscription-based format, such as CorelDRAW Graphics Suite, tends to offer low monthly costs and provides built-in upgrades. By upgrading software on a regular basis, users can ensure they are achieving the latest advantages in efficiency, waste reduction, and color management, without having to go through the costly and time-consuming process of vetting, purchasing, installing, and training staff on new capital equipment.

While keeping an eye on the latest hardware and ensuring that current equipment assets are not becoming obsolete is important, print service providers that maintain a regular schedule of evaluating, upgrading, and updating their software solutions can maximize the lifespan of their production equipment and continue to meet customer needs.

Graphic design software evaluation process

When assessing a graphic design software solution, print service providers should understand where current inefficiencies in their production process can be found. Of particular importance is accuracy of graphic reproduction, as evidenced by the 200 respondents in this survey, color management and eliminating rework remain areas of struggle.

McGrew recommends that every graphic design tool user should book time on their calendar to review their current software status.

" If the tools are not updated as new revisions become available, opportunities for gaining more efficiency in design development and proofing may be lost. Tool developers should make the investment in adding new features as requested by their users and look ahead to emerging technology options to keep their solutions relevant. "

-Industry Analyst Pat McGrew (McGrewGroup)

At a time when brand owners and marketers are becoming increasingly stringent in their color demands and print service providers are often producing applications across multiple print technologies spanning conventional and digital platforms, maintaining software tools that can assist in color reproduction is key.

Are you ready to start assessing graphic design software? Contact our sales team to learn more about CorelDRAW Graphics Suite.

Production efficiency

Printers have demonstrated a need for improvement in meeting customer expectations on their first attempt, thereby improving production efficiency and reducing the need for reruns.

While it may not be reasonable to expect that a printer will never make an error or otherwise run a job that requires a rerun, just 61% of respondents strongly agreed that their company consistently produces print jobs to their customers’ standards on the first attempt.

Having to get jobs back on press for reruns is time consuming, costly, and can have residual effects due to equipment being tied up and preventing subsequent jobs from getting on press. With the latest in graphic design software, print service providers can better ensure that the output customers will see will match their expectations, and maximize the collaborative tools within the software that foster communication throughout the production process.

Despite the advantages provided by graphic design software, however, print service providers are often hesitant to upgrade their software solutions due to misconceptions about how software upgrades may negatively affect their bottom line.

These misconceptions over potential workflow disruptions or compatibility issues are plaguing printers seeking maximum efficiency. While printers may feel comfortable believing that their workflow is not broken and therefore there is no need to fix it, inexpensive design software upgrades can lead to significant advantages at minimal cost.

Capital equipment expenditures may be enticing given the excitement that a new press can bring to an organization, but for printers seeking to consistently stay ahead of the competition, a focus on software can be the secret ingredient to long lasting success.

Conclusions and recommendations

Graphic design software touches just about every aspect of print production, and printers, agencies, brand owners, and marketers should be cognizant of the solutions they use and the advantages they bring to the process. In an environment that stresses efficiency, productivity, and accuracy, the latest advancements in graphic design software can offer cost-effective methods of maximizing the speed of production and ensuring customer expectations are met on the first try.

Based on the data gathered by this survey, commercial printers can engage the following tactics and activities to maximize efficiency and reduce waste in 2023 (and beyond):

- Upgrading their graphic design software

- Minimizing printing reruns by streamlining the prepress process

- Improve printing accuracy with better staff training and software solutions

- Enhance color management and therefore print outputs

- Increase the use of design-focused cloud collaboration technologies to streamline communication processes, particularly shortening internal and external stakeholder review timeframes

"CorelDRAW Graphics Suite is pivotal to helping us deliver print on-demand capabilities across North America. It helps reduce our costs, increases output, and minimizes waste so we can do more for less for our trusted clients."

-Justin Nichols, TMS Inc